Demand Flow Technology (DFT) is a manufacturing strategy that aligns production with customer demand. It focuses on reducing waste and improving efficiency.

DFT originated from the principles of lean manufacturing and just-in-time production. By synchronizing manufacturing processes with real-time customer demand, DFT aims to minimize inventory costs and eliminate overproduction. This approach enhances flexibility and responsiveness, enabling companies to meet market fluctuations effectively.

Implementing DFT involves using advanced planning tools and data analytics to forecast demand accurately. It also emphasizes continuous improvement and employee involvement. Businesses adopting DFT can achieve higher productivity, better resource utilization, and improved customer satisfaction. Overall, Demand Flow Technology offers a strategic advantage in today’s competitive and dynamic market.

Introduction To Demand Flow Technology

Demand Flow Technology (DFT) is a modern manufacturing strategy. It helps businesses become more efficient. DFT focuses on aligning production with customer demand. This approach reduces waste and improves productivity.

The Concept

Demand Flow Technology is all about balance. It ensures production matches customer needs. This method uses real-time data. This data helps in making quick adjustments. DFT reduces excess inventory. It also minimizes production delays.

Key features of DFT include:

- Real-time data usage

- Quick adjustments in production

- Waste reduction

- Improved efficiency

Historical Evolution

DFT has evolved over time. It started in the 1980s. Businesses needed a better way to manage production. Traditional methods were not enough. DFT came as a solution.

Here is a brief timeline of its evolution:

| Year | Development |

|---|---|

| 1980s | DFT was introduced |

| 1990s | Adoption increased in manufacturing |

| 2000s | Technology integration became common |

| 2010s | Real-time data usage became standard |

Today, DFT is widely used. It helps businesses stay competitive. DFT continues to evolve with new technologies. Businesses now rely on it for better production management.

Credit: www.youtube.com

Key Principles Of Demand Flow Technology

Understanding the Key Principles of Demand Flow Technology is crucial for optimizing production processes. Demand Flow Technology (DFT) ensures that production meets customer demand efficiently. This approach minimizes waste and maximizes productivity.

Demand-driven Approach

DFT focuses on a demand-driven approach. This approach aligns production rates with customer demand. It avoids overproduction and underproduction. The goal is to match supply with demand seamlessly.

- Customer demand dictates production schedules.

- Inventory levels are minimized.

- Production is flexible and responsive.

By following these principles, businesses can reduce waste. They can also improve customer satisfaction. The demand-driven approach ensures that resources are used efficiently.

Process Optimization

Process optimization is another key principle of DFT. It involves streamlining operations to enhance efficiency. This means eliminating non-value-added activities.

- Identifying and eliminating bottlenecks.

- Continuous improvement of processes.

- Implementing best practices in production.

Optimized processes lead to faster production times. They also ensure consistent product quality. This results in better utilization of resources.

| Principle | Description |

|---|---|

| Demand-Driven Approach | Aligns production with customer demand to avoid waste. |

| Process Optimization | Streamlines operations and eliminates non-value-added activities. |

Understanding these principles helps businesses achieve efficient production. They can meet customer needs effectively. This leads to higher profitability and customer loyalty.

Benefits Of Implementing Demand Flow Technology

Demand Flow Technology offers numerous advantages. It helps businesses adapt to market changes quickly. This flexibility leads to better efficiency and cost savings. Let’s explore some key benefits.

Enhanced Supply Chain Flexibility

Demand Flow Technology enhances supply chain flexibility. It allows businesses to adjust production levels. This adaptability ensures that supply meets demand precisely. Businesses can respond swiftly to market shifts. They can manage resources more effectively. This reduces waste and improves overall efficiency.

Reduced Inventory Costs

One major benefit is reduced inventory costs. Demand Flow Technology helps maintain optimal inventory levels. Businesses avoid overstocking and stockouts. This balance reduces storage costs and minimizes losses. It also frees up capital for other investments. Efficient inventory management leads to cost savings.

Improved Customer Satisfaction

Improved customer satisfaction is another key benefit. Demand Flow Technology ensures timely delivery of products. Customers receive what they need, when they need it. This reliability boosts customer trust and loyalty. Happy customers are more likely to return and recommend the business. This leads to increased sales and growth.

Credit: m.facebook.com

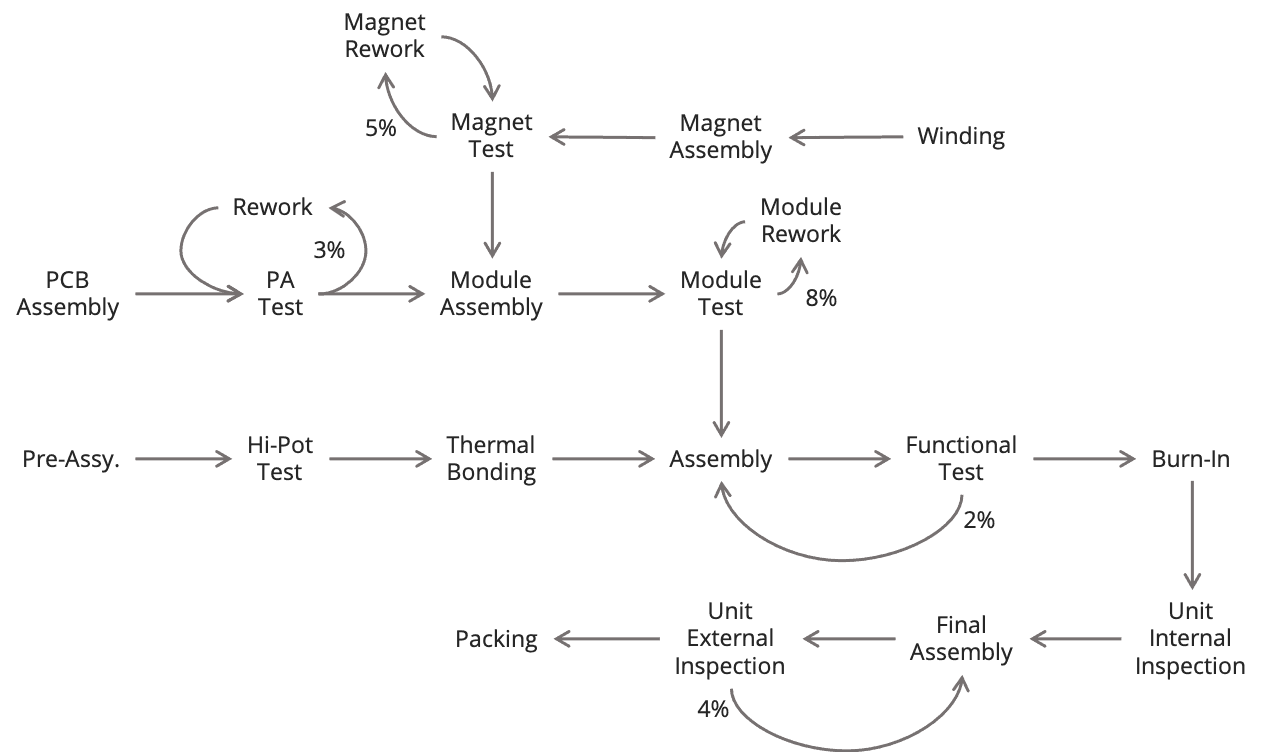

Demand Flow Technology In Action

Demand Flow Technology (DFT) changes how businesses operate. It boosts efficiency and reduces waste. Businesses use DFT to match production with customer demand. This section explores real-world examples of DFT in action.

Case Study: Manufacturing Sector

In the manufacturing sector, DFT improves production efficiency. Let’s look at a car factory. The factory uses DFT to align production with orders. This reduces excess inventory and saves money.

Here’s a simple table showing the impact:

| Before DFT | After DFT |

|---|---|

| High inventory costs | Reduced inventory costs |

| Long production cycles | Shorter production cycles |

| Frequent delays | Timely deliveries |

Case Study: Retail Industry

In retail, DFT enhances inventory management. A clothing store uses DFT to track sales in real-time. This helps the store to stock popular items while avoiding overstocking.

Benefits of DFT in retail include:

- Better stock levels

- Faster restocking

- Increased customer satisfaction

Both cases show the power of Demand Flow Technology. It makes businesses more efficient and responsive.

Integrating Demand Flow Technology With Existing Systems

Integrating Demand Flow Technology (DFT) with existing systems can seem complex. This integration brings many benefits for businesses. It streamlines operations and enhances efficiency.

Understanding how DFT fits into your current systems is key. Let’s explore how DFT can work with ERP systems and improve data analytics and demand forecasting.

Erp And Dft Compatibility

ERP systems manage many business processes. They handle inventory, order processing, and more. Integrating DFT with ERP systems enhances these capabilities.

DFT aligns production with demand. This reduces waste and increases efficiency. Here’s a simple table showing the benefits of integrating DFT with ERP systems:

| ERP Feature | Benefit with DFT |

|---|---|

| Inventory Management | Reduces excess stock |

| Order Processing | Speeds up order fulfillment |

| Production Planning | Aligns with actual demand |

Data Analytics And Demand Forecasting

Data analytics is crucial for any business. Combining DFT with data analytics improves demand forecasting. This leads to better decision-making.

With DFT, businesses can analyze real-time data. This helps predict future demand more accurately. Here are some key points:

- Real-time data analysis

- Improved demand prediction

- Enhanced operational efficiency

Using DFT, businesses can identify trends and patterns. This enables proactive responses to market changes. DFT makes data more actionable and useful.

Challenges And Solutions

Demand Flow Technology (DFT) revolutionizes production processes. Yet, it presents several challenges. Overcoming these hurdles is crucial. Let’s explore the challenges and solutions in implementing DFT.

Addressing Implementation Hurdles

Implementing DFT can be tough. The transition from traditional methods is challenging. Here are common hurdles:

- Lack of Training: Employees may lack DFT skills.

- Resistance to Change: Some resist new methods.

- Initial Costs: Investing in new tools is expensive.

Solutions to these hurdles include:

- Training Programs: Offer comprehensive training sessions.

- Change Management: Communicate benefits clearly.

- Cost-Benefit Analysis: Highlight long-term savings.

Maintaining Continuous Improvement

Continuous improvement is key in DFT. It involves regular evaluations. This ensures processes remain efficient.

Strategies for maintaining improvement:

- Regular Audits: Conduct frequent assessments.

- Feedback Loops: Encourage employee feedback.

- Technology Upgrades: Adopt the latest tools.

Implementing these strategies fosters a culture of excellence. It ensures the DFT system evolves over time.

Future Of Demand Flow Technology

The future of Demand Flow Technology (DFT) promises exciting advancements. This technology will transform industries with enhanced efficiency and productivity.

Technological Advances

Technological advances will play a crucial role in DFT’s future.

- Artificial Intelligence: AI will optimize demand flow processes.

- Machine Learning: ML algorithms will predict demand with high accuracy.

- IoT Integration: IoT devices will provide real-time data for better decision-making.

These technologies will streamline operations and reduce waste. The integration of blockchain will ensure transparency and security in supply chains.

Expanding Applications

DFT’s applications will expand across various industries.

- Manufacturing: DFT will reduce production downtime and improve output quality.

- Healthcare: Hospitals will manage resources better, improving patient care.

- Retail: Retailers will optimize inventory and enhance customer satisfaction.

In the logistics sector, DFT will streamline transportation and warehousing. This will lead to cost savings and faster delivery times.

DFT will also impact the energy sector. Power grids will balance supply and demand more efficiently.

| Industry | Impact of DFT |

|---|---|

| Manufacturing | Reduced downtime, improved output |

| Healthcare | Better resource management, improved care |

| Retail | Optimized inventory, enhanced satisfaction |

| Logistics | Streamlined transport, cost savings |

| Energy | Balanced supply and demand |

Credit: highimpactcs.com

Getting Started With Demand Flow Technology

Demand Flow Technology (DFT) helps businesses streamline their production processes. It focuses on reducing waste and improving efficiency. Implementing DFT can transform your operations. Let’s explore how to get started.

Steps For Implementation

Follow these steps to implement Demand Flow Technology:

- Assess your current processes. Identify areas that need improvement.

- Define clear objectives. Set measurable goals for the changes you want.

- Create a project team. Ensure you have the right skills and knowledge.

- Develop a detailed plan. Outline the steps and resources needed.

- Train your staff. Ensure everyone understands the new processes.

- Start with a pilot project. Test the changes on a small scale first.

- Monitor and review. Collect data to evaluate the pilot’s success.

- Roll out full implementation. Apply the changes across the entire operation.

Selecting The Right Tools And Partners

Choosing the right tools and partners is crucial for successful DFT implementation.

| Tool | Description |

|---|---|

| ERP Software | Integrates all facets of an operation, including planning, manufacturing, sales, and marketing. |

| Lean Manufacturing Tools | Helps reduce waste and improve efficiency in production processes. |

| Data Analytics Tools | Provides insights into production data to make informed decisions. |

Identify partners with experience in DFT. They can provide guidance and support. Look for:

- Consultants with a proven track record.

- Vendors offering reliable tools and services.

- Industry experts who understand your specific needs.

Establish clear communication with your partners. Ensure everyone is aligned with your goals. Regular meetings and updates can help maintain progress.

Frequently Asked Questions

What Is Demand Flow Technology?

Demand Flow Technology (DFT) is a production methodology. It optimizes manufacturing processes. DFT aims to meet customer demand precisely. It reduces waste and increases efficiency. This leads to cost savings.

How Does Demand Flow Technology Work?

DFT works by aligning production with real-time demand. It uses data and analytics. This minimizes inventory and streamlines operations. The goal is to produce only what is needed.

What Are The Benefits Of Dft?

DFT offers several benefits. It reduces waste and lowers costs. It improves efficiency and customer satisfaction. It also enhances flexibility and responsiveness in production.

Who Can Implement Demand Flow Technology?

Any manufacturing business can implement DFT. It suits various industries. From automotive to electronics, DFT is adaptable. It requires a commitment to process optimization.

Conclusion

Demand Flow Technology optimizes production processes, ensuring efficiency and cost-effectiveness. This method adapts to real-time demand changes. Companies can reduce waste, enhance productivity, and meet customer needs better. Embracing Demand Flow Technology can give businesses a competitive edge. Stay ahead by integrating this innovative approach into your operations.

Leave a Reply

You must be logged in to post a comment.