A standard truck of concrete typically holds 8 to 10 cubic yards. The exact amount can vary by truck size.

Concrete delivery by truck is a common requirement for construction projects. A typical concrete truck carries between 8 to 10 cubic yards of concrete, making it ideal for medium to large projects. Knowing the capacity helps in planning and budgeting effectively.

This ensures you order the right amount without wastage. Concrete trucks offer a practical solution for transporting large quantities of concrete efficiently. Their capacity is crucial for timely project completion. Always check with your supplier to confirm the truck’s capacity. This avoids any unexpected issues on the delivery day. Proper planning ensures smooth construction processes and cost efficiency.

Concrete Yard Basics

Understanding concrete measurements can be confusing. Especially when dealing with cubic yards. Knowing how to measure correctly ensures you order the right amount of concrete. This section explains the basics of concrete yards.

Definition Of A Cubic Yard

A cubic yard is a measure of volume. It equals 27 cubic feet. Imagine a cube that is 3 feet long, 3 feet wide, and 3 feet high. That cube is one cubic yard. This unit is common in construction.

Concrete is often sold by the cubic yard. Knowing this helps in planning your projects better. Here is a simple table to visualize:

| Length (ft) | Width (ft) | Height (ft) | Volume (cubic yards) |

|---|---|---|---|

| 3 | 3 | 3 | 1 |

| 6 | 3 | 3 | 2 |

| 9 | 3 | 3 | 3 |

Why Measurement Matters

Measurement accuracy ensures you order the right amount of concrete. Ordering too much or too little can be costly. Here are the main reasons:

- Cost Efficiency: Exact measurement avoids wasting money.

- Project Success: Accurate amounts ensure project completion without delays.

- Environmental Impact: Reduces unnecessary concrete waste.

Use the right measurements to plan and budget your project effectively. Precision helps in achieving the desired outcomes.

Calculating Concrete Needs

Understanding how much concrete you need is crucial for any project. Knowing the exact amount prevents waste and ensures a smooth process. Let’s break down the steps involved.

Project Planning

Proper project planning is the first step. Start by identifying the dimensions of the area to be concreted. Measure the length, width, and depth in feet. Write these numbers down for accurate calculations.

- Measure the length in feet

- Measure the width in feet

- Measure the depth in feet

Good planning helps to minimize errors. It also ensures that you order the right amount of concrete.

Volume Calculation

Now, let’s calculate the volume. Use the formula: Volume = Length x Width x Depth. For example, if your area is 10 feet long, 5 feet wide, and 0.5 feet deep, the volume is:

Volume = 10 ft x 5 ft x 0.5 ft = 25 cubic feet

Convert cubic feet to cubic yards since concrete is sold by the yard. Use this conversion:

1 cubic yard = 27 cubic feet

So, for our example:

25 cubic feet ÷ 27 = 0.93 cubic yards

Now you know how much concrete you need.

| Length (ft) | Width (ft) | Depth (ft) | Volume (cubic yards) |

|---|---|---|---|

| 10 | 5 | 0.5 | 0.93 |

For larger projects, calculate each section separately. Add the volumes together to get the total.

- Measure each section

- Calculate the volume for each

- Add the volumes together

Following these steps ensures you order the right amount of concrete. Happy building!

Concrete Truck Capacities

Concrete trucks come in different sizes. Each truck size offers unique benefits. Understanding truck capacities helps in planning your project efficiently.

Standard Truck Sizes

Concrete trucks are available in a range of sizes. The most common sizes include:

- 5-yard trucks

- 8-yard trucks

- 10-yard trucks

The 10-yard truck is the most popular. It delivers a good balance of capacity and maneuverability.

Load Limitations

Each truck has a maximum load limit. Exceeding this limit can cause problems. Here are the typical load limitations:

| Truck Size (yards) | Max Load (cubic yards) |

|---|---|

| 5-yard | 5 cubic yards |

| 8-yard | 8 cubic yards |

| 10-yard | 10 cubic yards |

Overloading a truck can lead to spills. It also increases wear and tear on the vehicle.

Ordering The Right Amount

Ordering the correct amount of concrete is crucial for any construction project. Knowing how many yards of concrete fit in a truck helps. This can save you time and money. Let’s explore how to avoid shortages and handle excess.

Avoiding Shortages

Shortages can delay your project and increase costs. Here are some tips to avoid them:

- Calculate the exact volume needed for your project.

- Add 10% extra to cover errors and spillage.

- Consider the size of the delivery truck.

Most trucks carry 8-10 cubic yards of concrete. Make sure your order aligns with this capacity. Use the table below to help calculate your needs:

| Project Type | Volume (Cubic Yards) |

|---|---|

| Small Patio | 1-2 |

| Driveway | 6-8 |

| Foundation | 10-12 |

Handling Excess

Sometimes, you may end up with excess concrete. Here’s how to handle it:

- Plan for extra areas to pour the leftover concrete.

- Use molds for small projects like stepping stones.

- Donate the excess to a local community project.

Having a plan for excess concrete prevents waste. It also saves on disposal costs. Keep these tips in mind to make your project smooth and efficient.

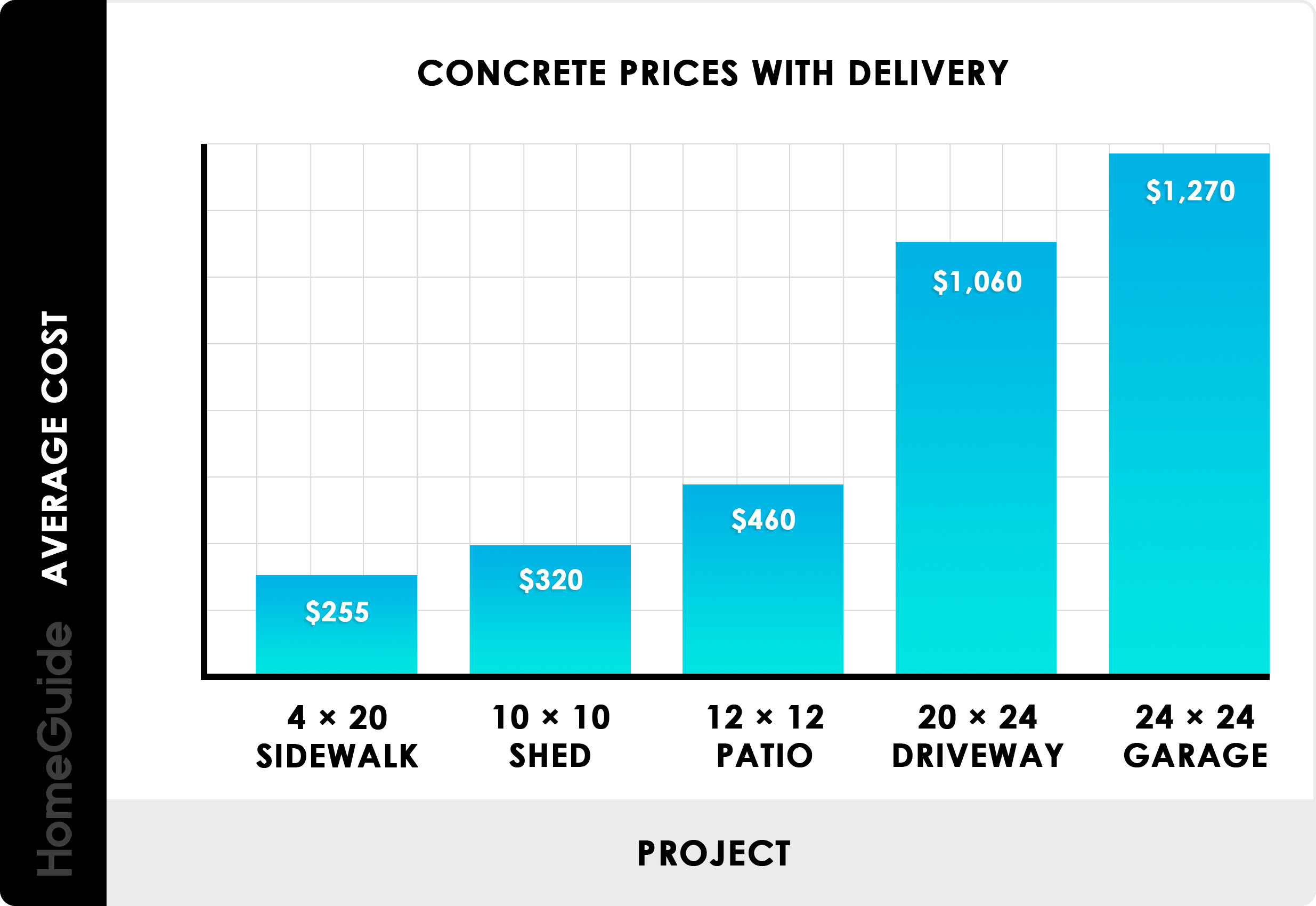

Cost Considerations

Understanding the cost considerations for a truck of concrete is crucial. This section will break down the main cost factors. It will help you make an informed decision.

Price Per Cubic Yard

The price per cubic yard of concrete is a primary factor. This price can vary based on several elements:

- Location

- Concrete quality

- Supplier rates

On average, the cost can range from $100 to $150 per cubic yard. It is always best to get multiple quotes. This ensures you get the best price.

Additional Fees

There are additional fees to consider beyond the base price. These fees can include:

- Delivery charges

- Fuel surcharges

- Environmental fees

- Short load fees

Delivery charges depend on the distance from the plant to the site. Fuel surcharges can fluctuate based on current fuel prices. Environmental fees cover the cost of waste disposal and recycling.

Short load fees apply if you order less than a full truckload. It is important to factor in these additional costs. They can significantly impact the total price.

Delivery And Pouring Tips

Delivering and pouring concrete requires proper planning. Follow these steps to ensure a smooth process. A truckload of concrete can be tricky, but with the right tips, you can manage it effectively.

Site Preparation

Proper site preparation is crucial. Clear the area of any debris. Make sure the ground is level. Mark the boundaries using stakes and strings.

Check for underground utilities. This helps in avoiding any damages. Ensure all necessary tools are available. These include wheelbarrows, shovels, and trowels.

| Tool | Purpose |

|---|---|

| Wheelbarrow | Transporting concrete |

| Shovel | Spreading concrete |

| Trowel | Smoothing surface |

Pouring Techniques

Use the right pouring techniques to get the best results. Start pouring from one end. Move steadily to the other end. This avoids uneven surfaces.

Work quickly but carefully. Concrete sets fast. Use a long screed to level the surface. Make sure to fill any low spots.

After leveling, use a bull float. This helps in smoothing the surface. Allow the concrete to set slightly before finishing.

- Start pouring from one end

- Move steadily to avoid uneven surfaces

- Work quickly to prevent premature setting

- Use a long screed for leveling

- Use a bull float for smoothing

Common Challenges

Transporting concrete involves several challenges. These can affect the overall project. Understanding these challenges helps in better planning.

Weather Impacts

Weather plays a significant role in concrete delivery. Rain can delay the process. Water can mix with concrete, causing issues. Cold weather may slow down the curing process. Hot weather can make concrete set too quickly. Monitoring the weather forecast is crucial. This helps in scheduling the delivery at the right time.

Last-minute Adjustments

Last-minute adjustments can be stressful. Sometimes, the project scope changes suddenly. This can affect the amount of concrete required. Miscalculations can lead to shortages or excess. Communicating clearly with the supplier is essential. Make sure to have a buffer for unexpected changes. This ensures the project runs smoothly without delays.

| Challenge | Impact | Solution |

|---|---|---|

| Rain | Delays and water mixing issues | Monitor weather and cover concrete |

| Cold Weather | Slows curing process | Use additives to speed up curing |

| Hot Weather | Quick setting of concrete | Schedule delivery early morning |

| Scope Changes | Quantity miscalculations | Maintain clear communication |

Frequently Asked Questions

How Many Yards In A Standard Truck Of Concrete?

A standard truck of concrete typically carries around 8 to 10 cubic yards. This can vary slightly depending on the truck’s capacity and the concrete supplier.

How Is Concrete Measured In A Truck?

Concrete is measured in cubic yards when loaded into a truck. This measurement helps determine the volume needed for construction projects.

What Factors Affect The Amount Of Concrete In A Truck?

Several factors, including truck size, concrete mix type, and project requirements, can affect the amount of concrete a truck can carry.

Can A Truck Carry More Than 10 Yards Of Concrete?

Most standard trucks are designed to carry up to 10 cubic yards. Special trucks or larger mixers might carry more, but this is less common.

Conclusion

Understanding the yardage in a truck of concrete is vital for planning construction projects. Accurate measurements ensure efficient usage and cost-effectiveness. Always consult with professionals for precise estimates. This knowledge helps in avoiding unnecessary expenses and delays. Proper planning leads to successful project completion and satisfaction.

Leave a Reply

You must be logged in to post a comment.