A standard concrete truck can hold about 8 to 10 cubic yards of concrete. This capacity varies based on the truck’s size.

Concrete trucks are essential for construction projects. They deliver ready-mix concrete efficiently to job sites. Knowing the truck’s capacity helps in planning and budgeting. With a range of 8 to 10 cubic yards, you can estimate the volume needed for your project.

This information is crucial for timely and cost-effective construction. Concrete delivery ensures consistent quality and saves time. It’s vital to coordinate with suppliers for optimal results. Understanding truck capacities aids in efficient project management. Proper planning ensures that you have the right amount of concrete. This minimizes waste and maximizes productivity.

Concrete Truck Basics

Understanding the basics of a concrete truck is essential. Concrete trucks carry and deliver fresh concrete to construction sites. They come in various sizes and capacities. Knowing their types and capacities helps in planning and executing construction projects efficiently.

Types Of Concrete Trucks

Concrete trucks come in several types. Each type serves a different purpose.

- Standard Transit Mixer: This is the most common type. It mixes concrete while traveling to the site.

- Volumetric Concrete Mixer: This type measures and mixes concrete on-site. It allows for precise control of concrete mix.

- Specialized Concrete Pumps: These trucks pump concrete to high or hard-to-reach places. They are crucial for tall buildings.

Truck Capacity Variations

Concrete trucks have different capacities. The capacity is measured in cubic yards.

| Truck Type | Capacity (Cubic Yards) |

|---|---|

| Small Truck | 4 to 6 cubic yards |

| Standard Truck | 8 to 10 cubic yards |

| Large Truck | 12 to 14 cubic yards |

The size of your project determines the truck capacity you need. Small projects need smaller trucks. Large projects require larger trucks.

Calculating Concrete Yards

A standard concrete truck typically carries around 8 to 10 cubic yards of concrete. This capacity ensures efficient delivery for various construction projects, minimizing the need for multiple trips.

Understanding Cubic Yards

Concrete is measured in cubic yards, not traditional linear yards.

One cubic yard is equivalent to a cube with sides measuring one yard each.

Formulas For Calculation

To calculate the volume of concrete needed:

- Multiply the length, width, and height to get cubic feet.

- Divide the total by 27 to convert to cubic yards.

For example, a 10×10 slab 4 inches thick is 1.23 cubic yards.

Factors Affecting Capacity

Understanding the factors affecting the capacity of a concrete truck is crucial. It helps to determine how much concrete can be delivered in one trip. Several elements influence the truck’s capacity. Below, we explore the significant factors affecting how many yards of concrete a truck can carry.

Weight Limits

Weight limits are a primary factor in a concrete truck’s capacity. Trucks must adhere to legal weight restrictions to ensure safety and road compliance. Exceeding these limits can lead to fines and operational issues.

- The typical weight limit for a concrete truck is approximately 80,000 pounds.

- The concrete itself is heavy. One cubic yard of concrete weighs roughly 4,000 pounds.

- The truck’s weight must also be considered. A fully-loaded truck usually weighs around 70,000 to 80,000 pounds.

Truck Dimensions

The physical dimensions of the truck affect how much concrete it can carry. Larger trucks can transport more concrete but must navigate through various terrains and sites.

| Truck Type | Capacity (cubic yards) |

|---|---|

| Standard Transit Mixer | 8 – 10 |

| Mini Mixer | 4 – 6 |

Standard transit mixers can carry 8 to 10 cubic yards of concrete. Smaller trucks, known as mini mixers, can carry 4 to 6 cubic yards.

Both weight limits and truck dimensions play crucial roles. They determine how many yards of concrete a truck can carry safely and legally.

Standard Truck Capacities

Understanding the standard truck capacities for concrete delivery is crucial. It helps in planning and managing construction projects effectively. The size of the truck determines how much concrete can be transported in one trip. There are two main types of concrete trucks: small trucks and large trucks.

Small Trucks

Small trucks are ideal for smaller construction projects. These trucks typically carry around 4 to 6 cubic yards of concrete. They are perfect for residential projects or minor commercial work. Here are some key points:

- Capacity: 4 to 6 cubic yards

- Ideal for small projects

- Easy to maneuver in tight spaces

These trucks are often used for driveways, sidewalks, and small foundations. Their compact size makes them useful in urban or confined areas.

Large Trucks

Large trucks are designed for bigger construction projects. These trucks can carry up to 10 cubic yards of concrete. They are suitable for commercial and industrial projects. Key features include:

- Capacity: Up to 10 cubic yards

- Suitable for large projects

- Efficient for bulk deliveries

Large trucks are often used for large foundations, commercial buildings, and infrastructure projects. They help reduce the number of trips needed, saving time and costs.

Delivery Considerations

Understanding how many yards of concrete a truck carries is crucial. Equally important are the delivery considerations. Proper planning ensures a smooth and efficient process.

Site Accessibility

Site accessibility is a key factor in concrete delivery. Ensure the truck has clear access to the site. Trucks need wide, stable paths to navigate safely. Check for any obstacles like low-hanging branches or tight turns.

Use the following checklist to assess site accessibility:

- Ensure a clear path for the truck

- Remove any obstructions

- Confirm ground stability

Weather Conditions

Weather conditions can significantly impact concrete delivery. Dry weather is ideal for concrete pouring. Wet conditions can cause delays and affect the concrete quality.

Monitor the weather forecast closely. Prepare for potential weather changes with these tips:

- Check the weather forecast daily

- Have tarps ready to cover the concrete

- Ensure the site is well-drained

Concrete sets best at moderate temperatures. Extreme heat or cold can cause issues. Plan the delivery during favorable weather conditions to ensure the best results.

Cost Implications

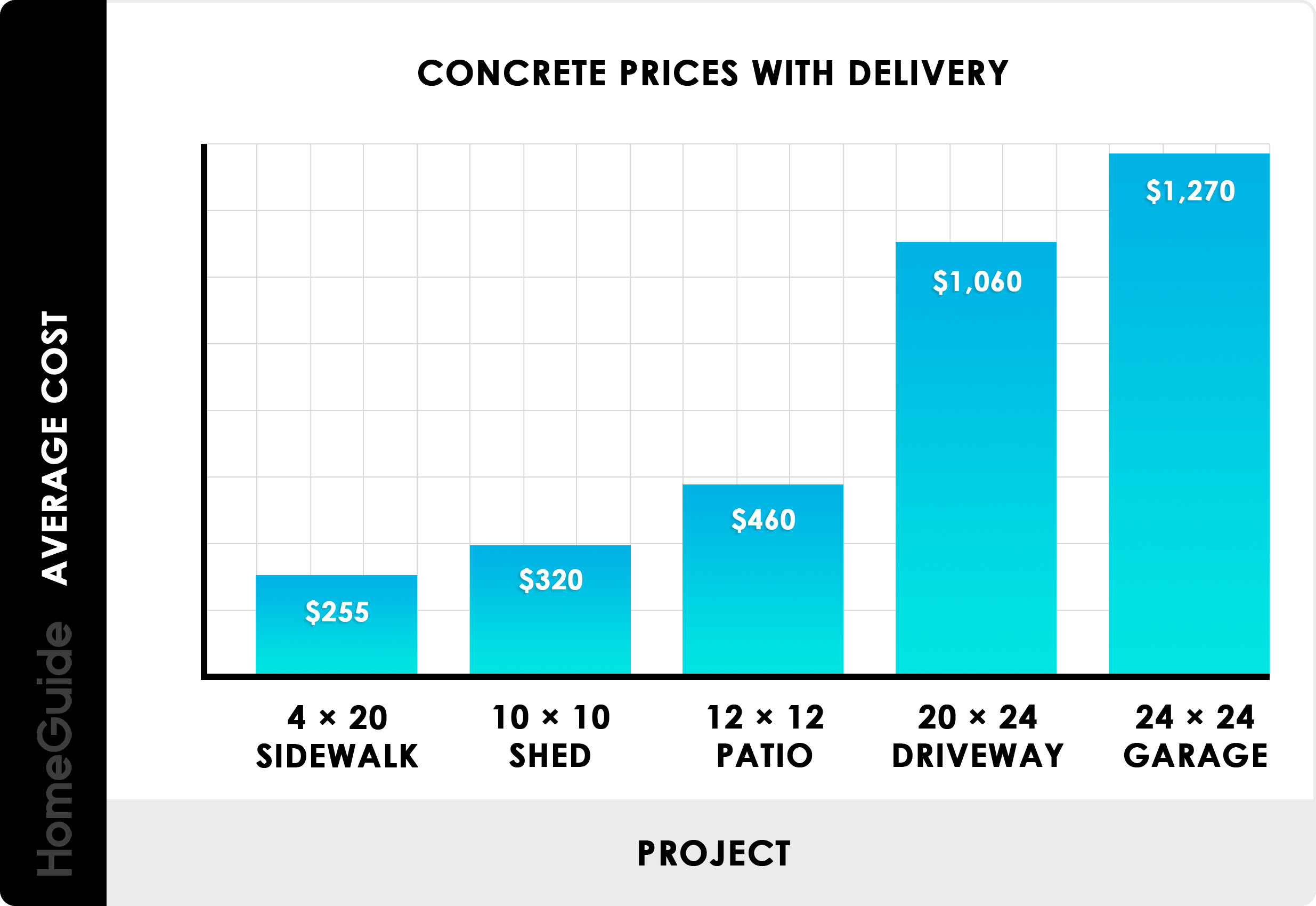

Understanding the cost implications of ordering concrete is crucial. This helps in budgeting for your project. The cost can vary based on several factors. These include the price per yard and additional fees.

Pricing Per Yard

The cost of concrete is typically measured per cubic yard. Prices can range from $100 to $150 per cubic yard. This price can fluctuate. Factors include the region and the quality of the concrete mix.

Here is a simple table to show the typical range:

| Concrete Quality | Price per Yard |

|---|---|

| Standard Mix | $100 |

| High-Strength Mix | $150 |

Knowing these prices helps you plan your budget better. Always check local prices before making a decision.

Additional Fees

When ordering concrete, be aware of additional fees. These fees can add up quickly. Here are some common ones:

- Delivery Fee: Usually charged based on distance.

- Short Load Fee: Applied if the order is less than a full truckload.

- Weekend Fee: Extra charge for deliveries on weekends.

- Fuel Surcharge: Added when fuel prices are high.

Here is a breakdown of potential additional costs:

| Fee Type | Cost |

|---|---|

| Delivery Fee | $50 – $100 |

| Short Load Fee | $100 – $200 |

| Weekend Fee | $30 – $50 |

| Fuel Surcharge | Varies |

Understanding these fees helps you avoid unexpected costs. Always ask your supplier about any additional charges.

Common Mistakes

Understanding how many yards of concrete fit in a truck is crucial. Avoiding common mistakes can save time and money. Here are some frequent errors to avoid.

Overestimating Needs

Overestimating concrete needs can lead to excess costs. Ordering too much concrete wastes resources. This mistake often happens due to poor calculations.

Use precise measurements for accurate estimates. Measure the area and depth correctly. Use a concrete calculator for better accuracy.

- Measure the area in square feet.

- Determine the depth in inches.

- Convert depth to feet (divide by 12).

- Multiply area by depth to find cubic feet.

- Convert cubic feet to cubic yards (divide by 27).

Ignoring Site Conditions

Site conditions affect concrete needs. Slopes, uneven ground, and obstacles can change requirements. Ignoring these factors leads to errors.

Inspect the site carefully. Note any slopes or obstacles. Adjust your calculations based on these conditions.

| Condition | Adjustment Needed |

|---|---|

| Slopes | Increase concrete amount |

| Uneven ground | Extra concrete for leveling |

| Obstacles | Account for additional work |

Frequently Asked Questions

How Many Yards Of Concrete Can A Truck Carry?

A typical truck can carry around 8 to 10 cubic yards of concrete, depending on the truck size and capacity. It’s essential to check the truck specifications to ensure the right amount for your project.

What Factors Affect The Amount Of Concrete In A Truck?

The size of the truck, its weight capacity, and the type of concrete mix being used are crucial factors. Additionally, the distance to the delivery site and any specific project requirements can impact the amount of concrete.

How To Calculate The Concrete Needed For A Project?

To calculate the concrete needed, multiply the length, width, and depth of the area to be filled with concrete. Then, divide the total by 27 (number of cubic feet in a cubic yard) to get the cubic yardage required for the project.

Can I Order A Partial Load Of Concrete For My Project?

Yes, many suppliers offer the option to order a partial load of concrete, allowing you to get the exact amount needed for your project. This can help reduce waste and ensure you have the right quantity of concrete.

Conclusion

Understanding how many yards of concrete a truck can hold is crucial for any construction project. Proper planning ensures efficient use of resources and time. Whether you’re working on a small patio or a large foundation, knowing the capacity helps.

Always consult with your concrete supplier for precise measurements.

Leave a Reply

You must be logged in to post a comment.